Robotic Car for Military Applications and STM32F4-based Stabilization Systems

Abstract:

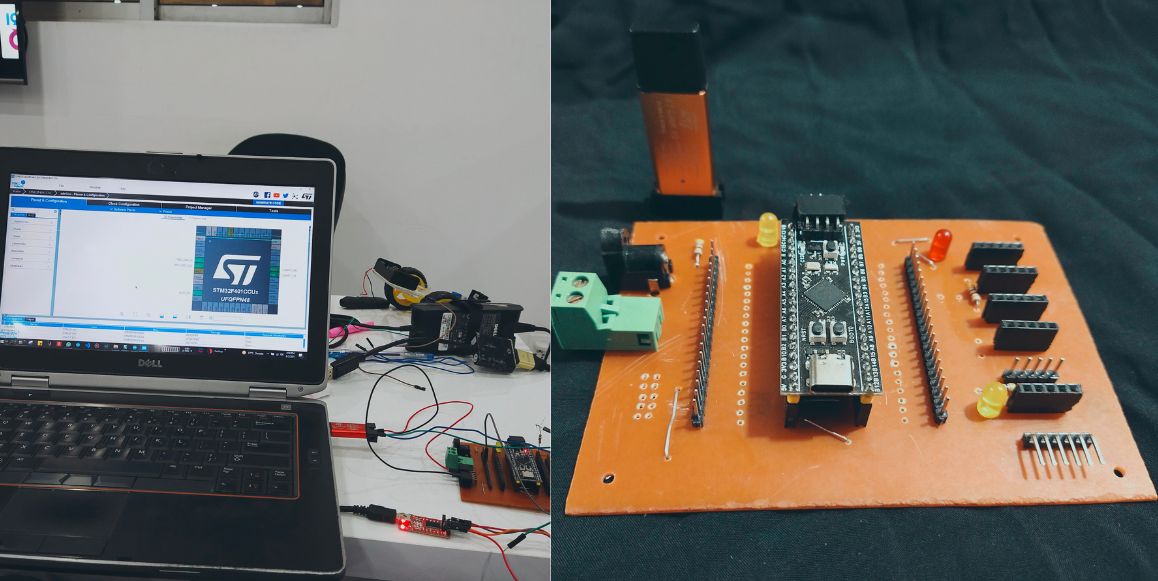

This document details the development and testing of two innovative systems: a robotic car designed for military applications, such as cutting hazardous wires to protect human lives, and a stabilization system for drones and robots using an STM32F4 microcontroller with Cube IDE. The robotic car employs servo motors and a Realtek chip for data logging and cloud communication. The stabilization system utilizes MPU6050 and other inertial measurement unit (IMU) chips to measure accelerometer and gyroscope values for maintaining stability. Both systems are built and tested on a vero board, providing a practical approach to prototyping and validation.

Objective:

The primary objectives of these projects are:

- Robotic Car:

- Enhance Safety: Reduce human exposure to dangerous situations by handling hazardous materials remotely.

- Improve Efficiency: Offer a reliable tool for military operations involving hazardous tasks.

- Enable Remote Operation: Allow safe and controlled operation from a distance.

- Stabilization System:

- Achieve Stability: Measure and process accelerometer and gyroscope values to stabilize drones and robots.

- Enhance Control: Improve the precision and responsiveness of movements in drones and robots.

Methodology:

The development and testing methodology involves several key stages:

- Design and Prototyping:

- Conceptualize the design of the robotic car and stabilization system.

- Build and test prototypes using a vero board to ensure practicality and ease of modifications.

- Hardware Selection and Assembly:

- Choose components including servo motors, STM32F4 microcontroller, MPU6050, other IMU chips, and a Realtek chip.

- Assemble the components on a vero board for initial prototyping and testing.

- Control System Development:

- Develop a control system using the STM32F4 microcontroller with Cube IDE.

- Implement algorithms to read accelerometer and gyroscope values from the MPU6050 and other IMU chips for the stabilization system.

- Communication and Data Logging:

- Integrate a Realtek chip for data logging and cloud communication for the robotic car.

- Ensure secure and reliable data transmission for performance analysis and monitoring.

- Testing and Validation:

- Conduct extensive testing on the vero board to validate the functionality and reliability of both systems.

- Refine the systems based on test results to optimize performance.

Future Works:

To further enhance and expand the capabilities of these systems, several future works are proposed:

- Enhanced Power Management:

- Develop more efficient power management solutions or integrate renewable energy sources like solar panels.

- Investigate higher-capacity batteries for extended operational times.

- Advanced Terrain Navigation:

- Implement advanced navigation systems for the robotic car to handle various terrains.

- Incorporate sensors and machine learning algorithms for autonomous navigation and obstacle avoidance.

- Increased Precision and Load Capacity:

- Upgrade servo motors and mechanical components to enhance the robotic arm’s precision and load capacity.

- Develop modular attachments for the robotic arm to handle different types of hazardous materials.

- Extended Communication Capabilities:

- Use advanced communication technologies such as satellite or mesh networks to extend the operational range.

- Implement robust encryption and anti-jamming techniques for secure communication.

- Autonomous Operational Capabilities:

- Explore the use of artificial intelligence and machine learning to develop autonomous operational capabilities.

- Integrate advanced sensors and decision-making algorithms to enable independent task performance.

Conclusion:

The development and testing of a robotic car for military applications and a stabilization system for drones and robots highlight significant advancements in enhancing safety and operational efficiency. Utilizing a vero board for building and testing provides a practical and flexible approach to prototyping. Ongoing research and development efforts aim to overcome current challenges and further expand the capabilities of these systems, ultimately providing valuable tools for military and robotics applications, protecting lives, and improving operational outcomes.