Fuel Injection Control

Abstract:

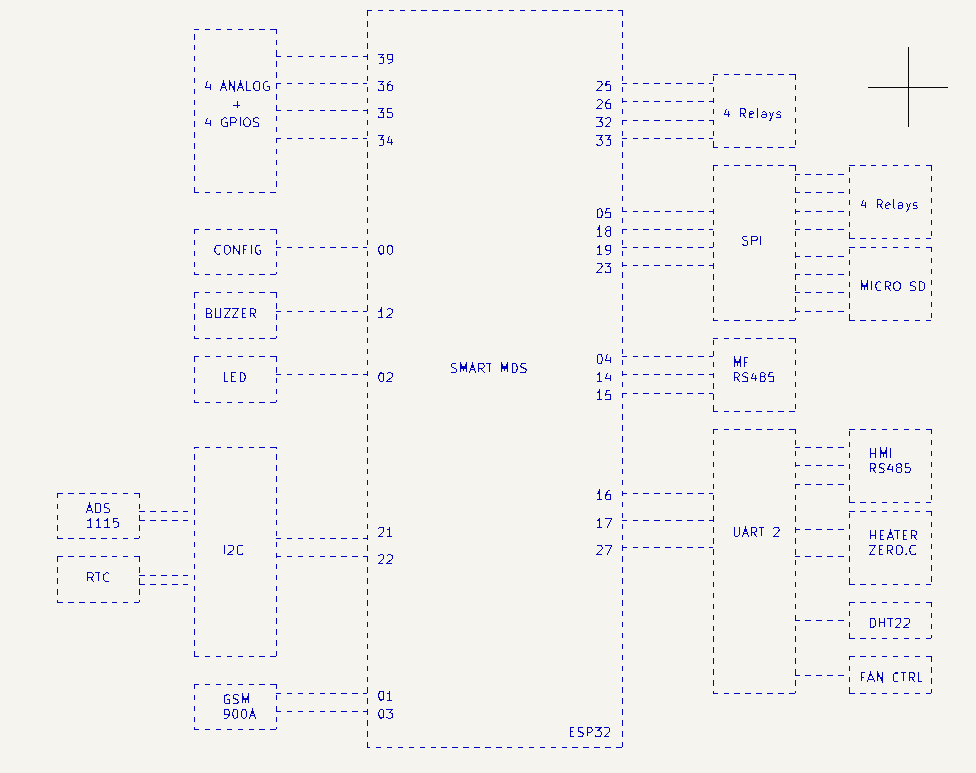

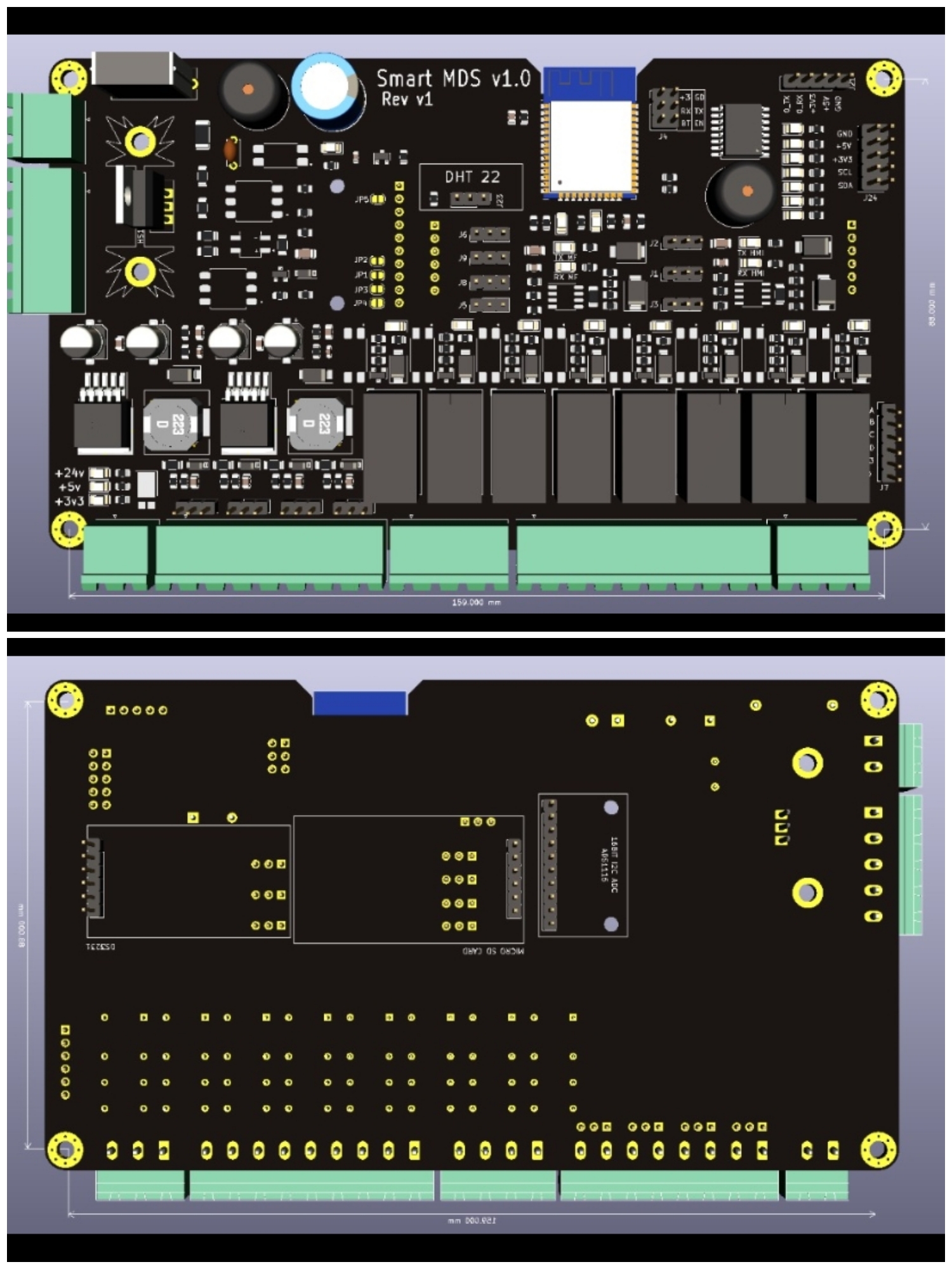

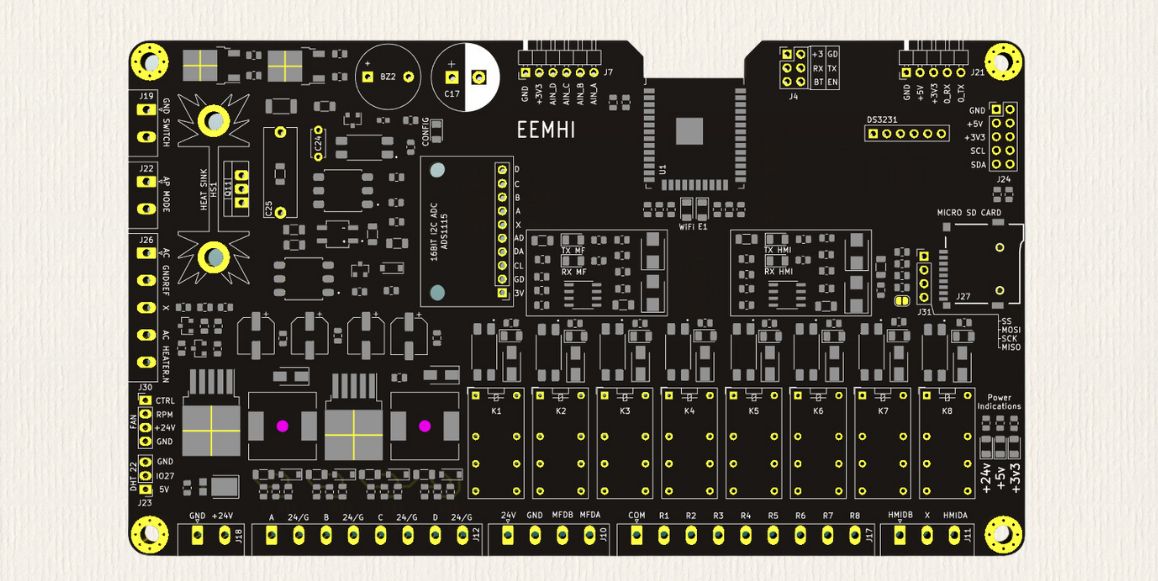

This project aims to develop a CNG (Compressed Natural Gas) gas control system utilizing the ESP32 microcontroller and several analog-to-digital converter (ADC) inputs. The system will monitor various parameters such as gas pressure, temperature, and flow rate to ensure safe and efficient operation of the CNG system. It will incorporate real-time data processing and control algorithms to regulate gas flow and maintain optimal conditions.

Terminology:

- CNG (Compressed Natural Gas): A type of fuel composed mostly of methane stored under high pressure, commonly used as a cleaner alternative to gasoline and diesel.

- ESP32: A versatile microcontroller chip known for its Wi-Fi and Bluetooth capabilities, widely used in IoT (Internet of Things) projects.

- ADC (Analog-to-Digital Converter): A component that converts analog signals (such as voltage levels) into digital values that can be processed by a digital system like a microcontroller.

- Gas Pressure: The force exerted by gas molecules per unit area, typically measured in units like psi (pounds per square inch) or bar.

- Temperature: The degree of hotness or coldness measured in degrees Celsius (°C) or Fahrenheit (°F).

- Flow Rate: The rate at which a fluid (in this case, CNG) flows through a system, usually measured in units like liters per minute (L/min) or cubic meters per hour (m³/h).

- Real-time Data Processing: The analysis and manipulation of data as it is received, enabling immediate responses and decision-making.

- Control Algorithms: Sets of rules and calculations used to regulate system parameters, such as gas flow, based on input data and predefined criteria.

- IoT (Internet of Things): The network of interconnected devices embedded with sensors, software, and other technologies to exchange data and perform tasks without human intervention.

- Regulation: The process of controlling or adjusting variables within specified limits to achieve desired system performance or outcomes.