Service

Mechanical Enclosure Designing

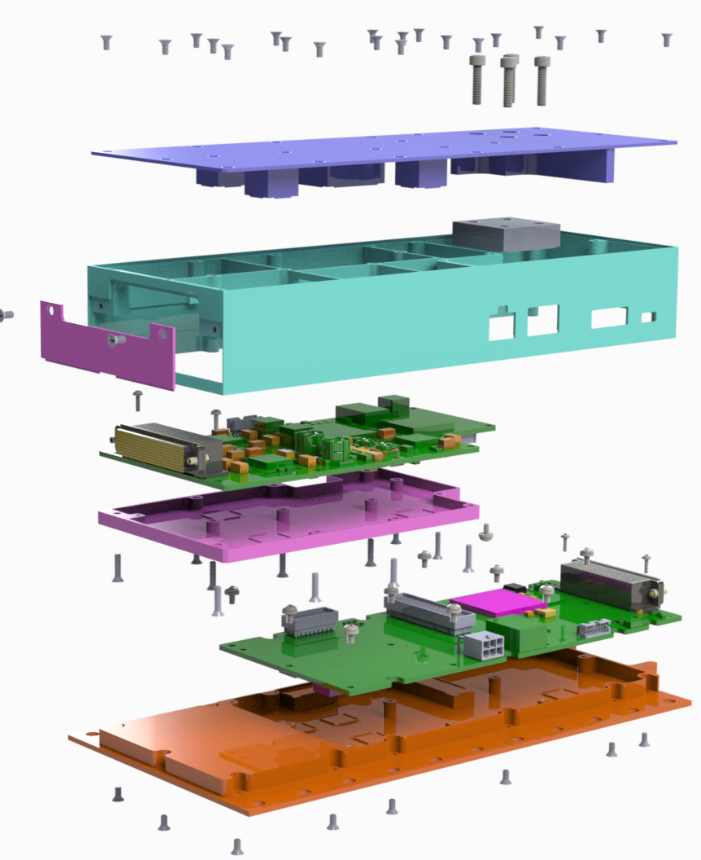

Mechanical Enclosure Designing

Overview

As a professional embedded systems engineer with a multidisciplinary team, I offer comprehensive end-to-end embedded project development services. These services include hardware and firmware design, 3D modeling, mechanical design, China-based dye production, molding, and relevant planning. The objective is to deliver robust, efficient, and tailored embedded solutions that meet the specific needs of each client.

Strategy

- Client Requirements Gathering

- Objective: Understand the client’s project needs and specifications.

- Details:

- Conduct an initial consultation with the client to discuss their project requirements, objectives, and constraints.

- Collect detailed technical specifications, including desired functionalities, performance metrics, hardware, software requirements, mechanical design needs, and manufacturing preferences.

- Identify the end application of the embedded system to ensure the design meets the intended use case.

- Feasibility Study and Preliminary Design

- Objective: Assess the feasibility of the project and create an initial design concept.

- Details:

- Evaluate the technical and financial feasibility of the project based on the client’s requirements.

- Perform a preliminary analysis to identify potential challenges and solutions, such as power management, signal integrity, EMI/EMC compliance, and mechanical constraints.

- Develop an initial hardware, firmware, and mechanical design concept using tools like Altium Designer for PCB design, IDEs for firmware development, and CAD software for 3D modeling and mechanical design.

- Provide the client with a preliminary design report and cost estimate for approval.

- Detailed Hardware, Firmware, and Mechanical Design

- Objective: Develop detailed hardware, firmware, and mechanical designs and validate their performance through simulations and prototyping.

- Details:

- Create detailed schematic diagrams and PCB layouts using advanced design software like Altium Designer or KiCad.

- Develop the firmware using appropriate development environments, ensuring efficient and reliable code.

- Design 3D models and mechanical components using CAD software.

- Perform simulations to validate the hardware design’s performance, including signal integrity analysis, thermal analysis, and power distribution analysis.

- Prototype the hardware and develop initial firmware to test basic functionalities.

- Create prototypes of mechanical components to validate fit, form, and function.

- Prototyping and Testing

- Objective: Manufacture prototype embedded systems and conduct thorough testing to ensure they meet the design specifications.

- Details:

- Coordinate with PCB fabrication, assembly partners, and China-based dye production and molding partners to produce prototype boards and mechanical components.

- Perform functional testing, signal integrity testing, and thermal testing on the prototypes, focusing on interfaces such as SPI, UART, and I2C.

- Test additional components like relays, IoT modules, and mechanical assemblies to ensure proper operation.

- Identify and resolve any issues found during testing, and iterate the design, firmware, and mechanical components if necessary.

- Document the testing process and results for client review.

- Integration and System Testing

- Objective: Integrate the hardware, firmware, and mechanical components into the final system and perform extensive system testing.

- Details:

- Integrate the hardware, firmware, and mechanical components, ensuring seamless operation of all elements.

- Conduct system-level testing to validate the overall functionality, performance, and reliability of the embedded system.

- Perform stress testing, environmental testing, and compliance testing as required.

- Optimize hardware, firmware, and mechanical designs based on testing results to ensure optimal performance.

- Final Design Review and Delivery

- Objective: Finalize the embedded system design and deliver all necessary documentation and files to the client.

- Details:

- Conduct a comprehensive design review with the client to ensure all requirements are met.

- Make any final adjustments to the design, firmware, and mechanical components based on client feedback.

- Prepare all necessary documentation, including design files, firmware source code, Gerber files, BOM (Bill of Materials), assembly drawings, mechanical CAD files, and test reports.

- Provide the client with the final design package and offer support for the initial production run if required.

- Deployment and Support

- Objective: Assist with the deployment of the embedded system and provide ongoing support.

- Details:

- Support the client during the initial deployment phase to ensure smooth integration and operation.

- Provide training and documentation to the client’s team for maintenance and troubleshooting.

- Offer ongoing support and maintenance services, including firmware updates, hardware modifications, mechanical part replacements, and technical assistance.