Service

IoT Boards Development

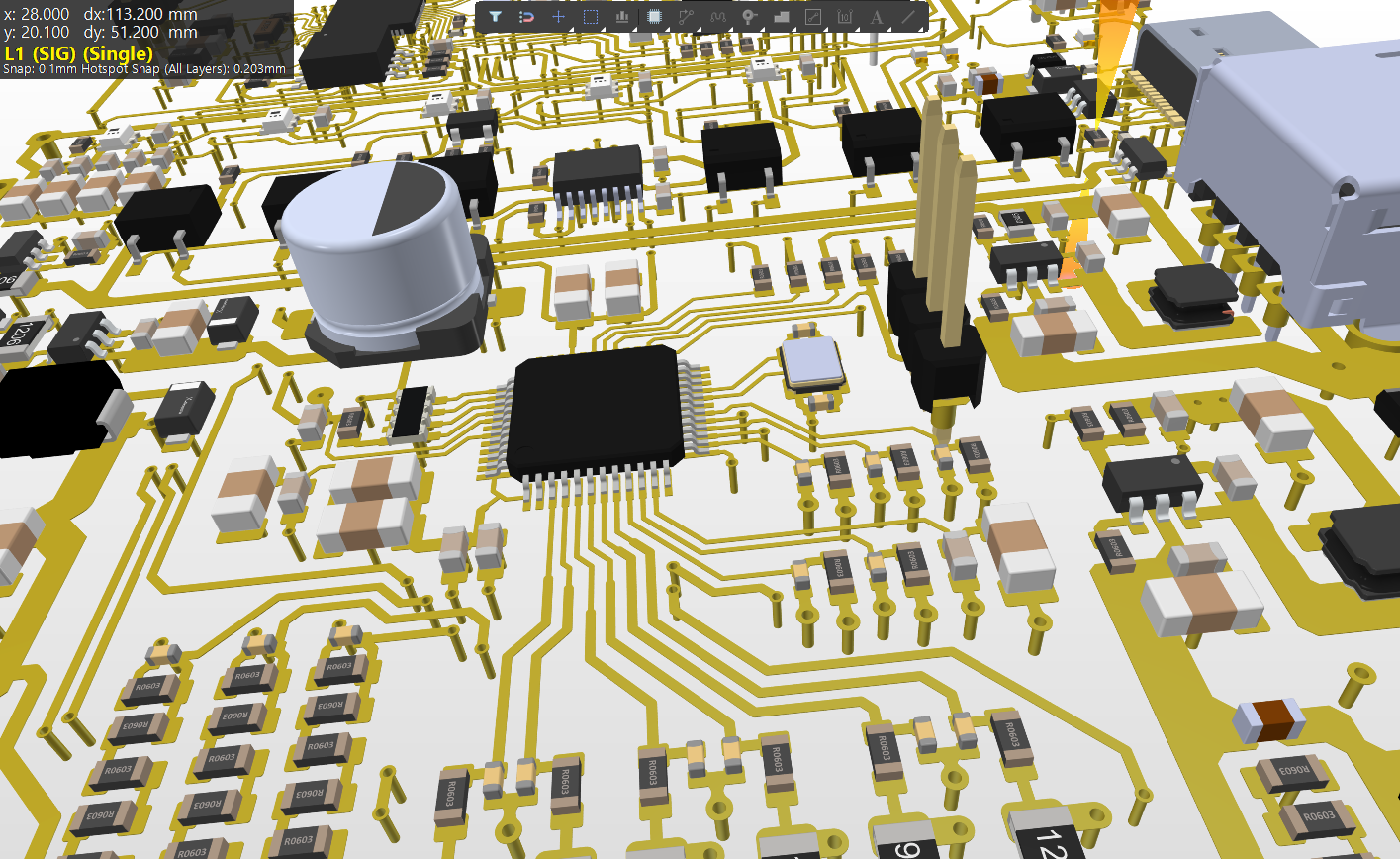

Overview

As a professional PCB design engineer, I offer specialized PCB design services for microcontrollers like ESP32, STM32, and ATmega328P. These services also cover simple level boards based on SPI, UART, I2C protocols, and various IoT and relay boards. The objective is to deliver customized, high-quality PCBs that meet the specific requirements of each project.

Strategy

- Client Requirements Gathering

- Objective: Understand the client’s project needs and specifications.

- Details:

- Conduct an initial consultation with the client to discuss their project requirements, objectives, and constraints.

- Collect detailed technical specifications, including the choice of microcontroller (ESP32, STM32, ATmega328P), communication protocols (SPI, UART, I2C), and additional components like relays or IoT modules.

- Identify the end application of the PCB to ensure the design meets the intended use case.

- Feasibility Study and Preliminary Design

- Objective: Assess the feasibility of the project and create an initial design concept.

- Details:

- Evaluate the technical and financial feasibility of the project based on the client’s requirements.

- Perform a preliminary analysis to identify potential challenges and solutions, such as power management, signal integrity, and EMI/EMC compliance.

- Develop an initial schematic diagram and layout concept using design software such as Altium Designer or KiCad.

- Provide the client with a preliminary design report and cost estimate for approval.

- Detailed Design and Simulation

- Objective: Develop a detailed PCB design and validate its performance through simulations.

- Details:

- Create detailed schematic diagrams and PCB layouts using advanced design software like Altium Designer and KiCad.

- Ensure adherence to design principles suitable for microcontrollers (ESP32, STM32, ATmega328P) and communication protocols (SPI, UART, I2C).

- Implement power supply circuits, decoupling strategies, and any necessary logic level conversions.

- Perform simulations to validate the design’s performance, including signal integrity analysis, thermal analysis, and power distribution analysis.

- Optimize the design based on simulation results to ensure reliability and performance.

- Prototyping and Testing

- Objective: Manufacture a prototype PCB and conduct thorough testing to ensure it meets the design specifications.

- Details:

- Coordinate with PCB fabrication and assembly partners to produce prototype boards.

- Perform functional testing, signal integrity testing, and thermal testing on the prototypes, focusing on interfaces such as SPI, UART, and I2C.

- Test additional components like relays and IoT modules to ensure proper operation.

- Identify and resolve any issues found during testing, and iterate the design if necessary.

- Document the testing process and results for client review.

- Final Design Review and Delivery

- Objective: Finalize the PCB design and deliver all necessary documentation and files to the client.

- Details:

- Conduct a comprehensive design review with the client to ensure all requirements, including those for microcontrollers and communication protocols, are met.

- Make any final adjustments to the design based on client feedback.

- Prepare all necessary documentation, including Gerber files, BOM (Bill of Materials), assembly drawings, and test reports.

- Provide the client with the final design package and offer support for the initial production run if required.