Robotic Car for Military Applications

Abstract:

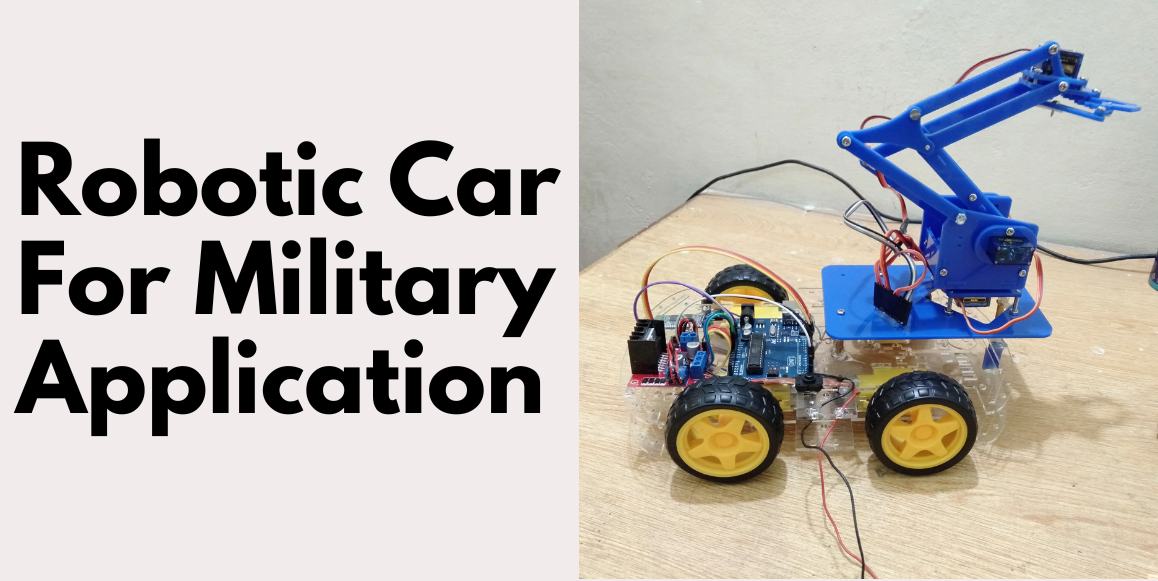

This document presents the design and development of a robotic car equipped with a single arm, intended for military applications such as cutting hazardous wires and protecting lives. The system is powered by servo motors and controlled via an application. Key components include potentiometers, an ATmega328P microcontroller, servo drivers, and a Realtek chip for data logging and cloud communication. This robotic solution aims to enhance safety in dangerous environments by allowing remote operation of tasks that would otherwise put human lives at risk.

Objective:

The primary objective of this project is to develop a robotic car capable of performing hazardous tasks in military environments, specifically cutting wires that may be dangerous or difficult for humans to handle. The system is designed to:

- Enhance Safety: Minimize human exposure to dangerous situations.

- Improve Efficiency: Provide a reliable and efficient tool for military operations involving hazardous materials.

- Facilitate Remote Operation: Allow operators to control the robot from a safe distance, thereby increasing operational safety.

Methodology:

The methodology followed in the development of the robotic car involves several key stages:

- Design and Prototyping:

– Conceptualize the design of the robotic car and its arm.

– Develop a prototype using 3D modeling and simulations to ensure feasibility.

- Hardware Selection and Assembly:

– Choose appropriate components including servo motors, potentiometers, ATmega328P microcontroller, and servo drivers.

– Assemble the robotic car and integrate the arm mechanism with precise control capabilities.

- Control System Development:

– Develop a control system using the ATmega328P microcontroller to interface with the servo motors and potentiometers.

– Implement a mobile application for remote control of the robotic car, providing real-time feedback and control over the arm’s movements.

- Communication and Data Logging:

– Integrate a Realtek chip to facilitate data logging and communication with the cloud.

– Ensure secure and reliable data transmission for operational monitoring and performance analysis.

- Testing and Validation:

– Conduct rigorous testing in controlled environments to validate the performance and reliability of the robotic car.

– Make necessary adjustments based on test results to optimize functionality.

Limitations:

While the robotic car presents significant advancements, it also has certain limitations:

- Battery Life: The operational time is limited by the battery capacity, which may require frequent recharging or replacement during extended missions.

- Terrain Adaptability: The robotic car’s performance can be affected by rough or uneven terrains, limiting its operational scope in certain environments.

- Load Capacity: The strength and precision of the arm are constrained by the servo motors’ capabilities, which may restrict the types and sizes of wires that can be effectively cut.

- Communication Range: The effectiveness of remote operation depends on the communication range of the Realtek chip, which may be affected by environmental factors or signal interference.

Future Works:

To address the current limitations and expand the capabilities of the robotic car, several future works are proposed:

- Enhanced Power Management:

– Develop more efficient power management systems or integrate solar charging solutions to extend operational time.

– Explore the use of higher-capacity batteries to support longer missions.

- Improved Terrain Navigation:

– Implement advanced suspension systems or tracks to enhance adaptability to various terrains.

– Integrate sensors and machine learning algorithms for autonomous terrain navigation and obstacle avoidance.

- Strength and Precision Upgrades:

– Upgrade servo motors and mechanical components to increase the load capacity and precision of the arm.

– Develop interchangeable arm attachments for handling different types of hazardous materials.

- Extended Communication Capabilities:

– Utilize advanced communication technologies such as satellite links or mesh networks to extend the operational range.

– Implement robust encryption and anti-jamming techniques to ensure secure and reliable communication.

- Autonomous Operation:

– Research and develop autonomous operational capabilities using artificial intelligence and machine learning to reduce reliance on human operators.

– Implement advanced sensors and decision-making algorithms to allow the robotic car to perform tasks independently.

Conclusion:

The development of a robotic car with a cutting arm for military applications demonstrates significant potential in enhancing safety and efficiency in hazardous environments. While there are limitations to be addressed, ongoing research and development efforts aim to overcome these challenges and further expand the capabilities of this innovative robotic solution. Through continuous improvement and technological advancements, this project seeks to provide a valuable tool for military operations, ultimately protecting lives and improving operational outcomes.